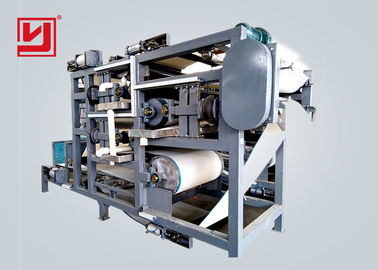

sludge dewatering treatment Belt Filter Press with professional sand washing plant manufacturer

Belt Filter Press Sludge dewatering treatment with high efficiency

Belt filter press is a widely used product for the efficient dewatering of sludge in urban, industrial, mining and aggregate wastewater treatment. It is especially suitable for the dewatering of tailings such as iron ore, copper ore, lead-zinc ore, fluorite ore, bauxite or rare earth ore; dewatering operations such as beneficiation wastewater, sand washing sludge and washing sludge.

Structure

Mixing device, cloth device, gravity dewatering device, wedge dewatering device, high pressure dewatering device for squeeze roller, automatic dosing system, air compressor, electrical control system, etc.

Working principle

1. Thick dewatering: chemical pretreatment stage.

The belt filter press has higher requirements for flocculation effect. This machine uses a unique dosing mixer to achieve rapid flocculation and achieve the best flocculation effect.

2. Gravity dewatering: gravity concentration dehydration stage.

The sludge is evenly fed into the mesh belt through the cloth bucket, and the sludge runs forward with the filter belt. The free water flows into the water tank through the filter belt under the action of its own weight. The main function is to remove the free water in the sludge and make the sludge flow. Reduced sex and prepared for further extrusion.

3. Low/medium pressure dewatering: wedge preloading dewatering stage.

After gravity dewatering, it is still difficult to meet the sludge flowability requirements of the press dewatering section. After this stage of slight extrusion dewatering, the sludge is smoothly pressed and dewatered.

4. High pressure dewatering: the depressurization stage of the clamp press.

The filter cake is repeatedly pressed and sheared around the press roll by the upper and lower filter belts, and a large amount of capillary water is removed to gradually reduce the moisture of the filter cake.

Technical parameter

|

Model

|

Feed Material

concentration

(%)

|

Filter Area

(m²)

|

Power

(KW)

|

Capacity

(t/h)

|

Weight

(kg)

|

Overall Dimension

(mm)

|

| YHDY1000 |

30-40 |

15.35 |

17.5 |

3-5 |

4000 |

6000*1700*2000 |

| YHDY1500 |

30-40 |

20.55 |

20 |

5-7 |

5200 |

8200*2200*1850 |

| YHDY2000 |

30-40 |

24.4 |

32.8 |

6-9 |

6100 |

9300*2700*1850 |

| YHDY2500 |

30-40 |

34.5 |

34.8 |

9-13 |

10600 |

10320*3200*2300 |

| YHDY3000 |

30-40 |

44.7 |

39.9 |

15-20 |

14800 |

14300*3700*2500 |

| YHDY3500 |

30-40 |

54 |

18-25 |

4.00-8.00 |

17400 |

14300*4300*2700 |

Main Features

1) The main machine is made of high-quality national standard square tube. The surface is sprayed with high-pressure sandblasting, descaling, descaling, spraying four layers of fluorocarbon paint, and resisting acid and alkali corrosion for more than ten years.

2) The key parts are made of high quality stainless steel, including main dewatering roller, fender, water tank, waterproof cover and nozzle.

3) The bearing seat is made of high-quality cast iron parts and fully sealed structure. The bearing is a domestic famous brand double-row roller bearing, which is guaranteed for three years.

4) Squeeze roller, drive roller and guide roller are high-quality seamless steel pipe outsourcing wear-resistant rubber for three years.

5) Use high-quality filter screen with high strength, good water permeability, easy to block, easy to clean and easy to disassemble. Different filter screens are selected according to different physical properties of sludge.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!